4-Stroke Internal Combustion Engine

|

4-Stroke Internal Combustion Engine |

|

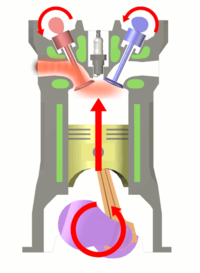

This is an animated computer drawing of one cylinder of the Wright brothers' 1903 aircraft engine. This engine powered the first, heavier than air, self-propelled, maneuverable, piloted aircraft; the Wright 1903 Flyer. The engine consisted of fourcylinders like the one shown above, with each piston connected to a common crankshaft. The crankshaft was connected to two counter-rotating propellers which produced the thrust necessary to overcome the drag of the aircraft.

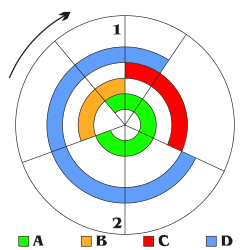

The brothers' design is very simple by today's standards, so it is a good engine for students to study to learn the fundamentals of engine operation. This type of internal combustion engine is called a four-stroke engine because there are four movements, or strokes, of the piston before the entire engine firing sequence is repeated. The four strokes are described below with some still figures. In the animation and in all the figures, we have colored the fuel/air intake systemred, the electrical system green, and the exhaust system blue. We also represent the fuel/air mixture and the exhaust gases by small colored balls to show how these gases move through the engine. Since we will be referring to the movement of various engine parts, here is a figure showing the names of the parts:

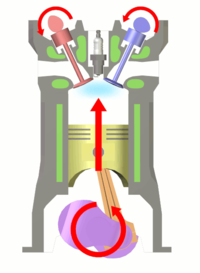

Intake Stroke

The engine cycle begins with the intake stroke as the piston is pulled towards the crankshaft (to the left in the figure).

The intake valve is open, and fuel and air are drawn past the valve and into the combustion chamber and cylinder from the intake manifold located on top of the combustion chamber. The exhaust valve is closed and the electrical contact switch is open. The fuel/air mixture is at a relatively low pressure (near atmospheric) and is colored blue in this figure. At the end of the intake stroke, the piston is located at the far left and begins to move back towards the right.

The cylinder and combustion chamber are full of the low pressure fuel/air mixture and, as the piston begins to move to the right, the intake valve closes.

Historical note - The opening and closing of the intake valve of the Wright 1903 engine was termed "automatic" by the brothers. It relies on the slightly lower pressure within in the cylinder during the intake stroke to overcome the strength of the spring holding the valve shut. Modern internal combustion engines do not work this way, but use cams and rocker arms like the brothers' exhaust system. Cams and rocker arms provide better control and timing of the opening and closing of the valves.

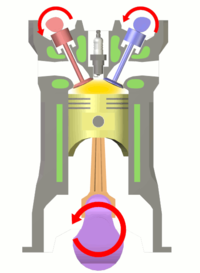

Compression Stroke

With both valves closed, the combination of the cylinder and combustion chamber form a completely closed vessel containing the fuel/air mixture. As the piston is pushed to the right, the volume is reduced and the fuel/air mixture is compressed during the compression stroke.

During the compression, no heat is transferred to the fuel/air mixture. As the volume is decreased because of the piston's motion, the pressure in the gas is increased, as described by the laws of thermodynamics. In the figure, the mixture has been colored yellow to denote a moderate increase in pressure. To produce the increased pressure, we have to do work on the mixture, just as you have to do work to inflate a bicycle tire using a pump. During the compression stroke, the electrical contact is kept opened. When the volume is the smallest, and the pressure the highest as shown in the figure, the contact is closed, and a current of electricity flows through the plug.

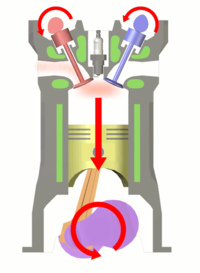

Power Stroke

At the beginning of the power stroke, the electrical contact is opened. The sudden opening of the contact produces a spark in the combustion chamber which ignites the fuel/air mixture. Rapid combustion of the fuel releases heat, and produces exhaust gases in the combustion chamber.

Because the intake and exhaust valves are closed, the combustion of the fuel takes place in a totally enclosed (and nearly constant volume) vessel. The combustion increases the temperature of the exhaust gases, any residual air in the combustion chamber, and the combustion chamber itself. From the ideal gas law, the increased temperature of the gases also produces an increased pressure in the combustion chamber. We have colored the gases red in the figure to denote the high pressure. The high pressure of the gases acting on the face of the piston cause the piston to move to the left which initiates the power stroke.

Unlike the compression stroke, the hot gas does work on the piston during the power stroke. The force on the piston is transmitted by the piston rod to the crankshaft, where the linear motion of the piston is converted to angular motion of the crankshaft. The work done on the piston is then used to turn the shaft, and the propellers, and to compress the gases in the neighboring cylinder's compression stroke. Having produced the igniting spark, the electrical contact remains opened.

During the power stroke, the volume occupied by the gases is increased because of the piston motion and no heat is transferred to the fuel/air mixture. As the volume is increased because of the piston's motion, the pressure and temperature of the gas are decreased. We have colored the exhaust "molecules" yellow to denote a moderate amount of pressure at the end of the power stroke.

Historical note - The method of producing the electrical spark used by the Wright brothers is called a "make and break" connection. There are moving parts located inside the combustion chamber. Modern internal combustion engines do not use this method, but instead use a spark plug to produce the ignition spark. A spark plug has no moving parts, which is much safer than the method used by the brothers.

Exhaust Stroke

At the end of the power stroke, the piston is located at the far left. Heat that is left over from the power stroke is nowtransferred to the water in the water jacket until the pressure approaches atmospheric pressure. The exhaust valve is then opened by the cam pushing on the rocker arm to begin the exhaust stroke.

The purpose of the exhaust stroke is to clear the cylinder of the spent exhaust in preparation for another ignition cycle. As the exhaust stroke begins, the cylinder and combustion chamber are full of exhaust products at low pressure (colored blue on the figure above.) Because the exhaust valve is open, the exhaust gas is pushed past the valve and exits the engine. The intake valve is closed and the electrical contact is open during this movement of the piston.

At the end of the exhaust stroke, the exhaust valve is closed and the engine begins another intake stroke.

Historical note - The exhaust system used by the Wright brothers caused the hot exhaust to exit each cylinder independently ... right next to the pilot. This engine was very loud as well. Modern automobiles collect the exhaust from all of the cylinders into an exhaust manifold (just like the intake manifold used by the brothers). The exhaust manifold passes the exhaust to the catalytic converter to remove dangerous gases, and then through the muffler to keep it quiet, and finally out the exhaust pipe.

You should now be able to make some sense from the animation at the top of this page. Notice that the crankshaft makes two revolutions for every one revolution of the cams. This motion is controlled by the timing chain. Also notice how the cam moves the exhaust valve at just the right time and how quickly the intake valve opens after the exhaust valve is closed. In real engine operation, the exhaust stroke can not push all of the exhaust out of the cylinder, so a real engine doesn't perform as well as the ideal engine described on this page. As the engine runs and heats up, the performance changes. Modern automobile engines adjust the fuel/air ratio with computer controlled fuel injectors to maintain high performance. The brothers just had to watch the horsepower of their engine drop from about 16 horsepower when the engine was first started to about 12 horsepower when it was running hot.

A four-stroke engine (also known as four-cycle) is an internal combustion engine in which the piston completes four separate strokes which constitute a single thermodynamic cycle. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed:

Nikolaus August Otto as a young man was a traveling salesman for a grocery concern. In his travels he encountered the internal combustion engine built in Paris by Belgian expatriate Jean Joseph Etienne Lenoir. In 1860, Lenoir successfully created a double-acting engine that ran on illuminating gas at 4% efficiency. The 18 litre Lenoir Engine produced only 2 horsepower. The Lenoir engine ran on illuminating gas made from coal, which had been developed in Paris by Philip Lebon.

In testing a replica of the Lenoir engine in 1861 Otto became aware of the effects of compression on the fuel charge. In 1862, Otto attempted to produce an engine to improve on the poor efficiency and reliability of the Lenoir engine. He tried to create an engine that would compress the fuel mixture prior to ignition, but failed as that engine would run no more than a few minutes prior to its destruction. Many other engineers were trying to solve the problem, with no success.

In 1864, Otto and Eugen Langen founded the first internal combustion engine production company, NA Otto and Cie (NA Otto and Company). Otto and Cie succeeded in creating a successful atmospheric engine that same year. The factory ran out of space and was moved to the town of Deutz, Germany in 1869 where the company was renamed to Deutz Gasmotorenfabrik AG (The Deutz Gas Engine Manufacturing Company). In 1872,Gottlieb Daimler was technical director and Wilhelm Maybach was the head of engine design. Daimler was a gunsmith who had worked on the Lenoir engine. By 1876, Otto and Langen succeeded in creating the first internal combustion engine that compressed the fuel mixture prior to combustion for far higher efficiency than any engine created to this time.

Daimler and Maybach left their employ at Otto and Cie and developed the first high-speed Otto engine in 1883. In 1885, they produced the first automobile to be equipped with an Otto engine. The Daimler Reitwagen used a hot-tube ignition system and the fuel known as Ligroin to become the world's first vehicle powered by an internal combustion engine. It used a four-stroke engine based on Otto's design. The following year Karl Benz produced a four-stroke engined automobile that is regarded as the first car.

In 1884, Otto's company, then known as Gasmotorenfabrik Deutz (GFD), developed electric ignition and the carburetor. In 1890, Daimler and Maybach formed a company known as Daimler Motoren Gesellschaft. Today, that company is Daimler-Benz.

The Atkinson cycle engine is a type of single stroke internal combustion engine invented by James Atkinson in 1882. The Atkinson cycle is designed to provide efficiency at the expense of power density, and is used in some modern hybrid electric applications.

The original Atkinson cycle piston engine allowed the intake, compression, power, and exhaust strokes of the four-stroke cycle to occur in a single turn of the crankshaft and was designed to avoid infringing certain patents covering Otto cycle engines.

Due to the unique crankshaft design of the Atkinson, its expansion ratio can differ from its compression ratio and, with a power stroke longer than its compression stroke, the engine can achieve greater thermal efficiency than a traditional piston engine. While Atkinson's original design is no more than a historical curiosity, many modern engines use unconventional valve timing to produce the effect of a shorter compression stroke/longer power stroke, thus realizing the fuel economy improvements the Atkinson cycle can provide.[4]

The diesel engine is a technical refinement of the 1876 Otto Cycle engine. Where Otto had realized in 1861 that the efficiency of the engine could be increased by first compressing the fuel mixture prior to its ignition, Rudolph Diesel wanted to develop a more efficient type of engine that could run on much heavier fuel. The Lenoir, Otto Atmospheric, and Otto Compression engines (both 1861 and 1876) were designed to run onIlluminating Gas (coal gas). With the same motivation as Otto, Diesel wanted to create an engine that would give small industrial concerns their own power source to enable them to compete against larger companies, and like Otto to get away from the requirement to be tied to a municipal fuel supply. Like Otto, it took more than a decade to produce the high compression engine that could self-ignite fuel sprayed into the cylinder. Diesel used an air spray combined with fuel in his first engine.

During initial development, one of the engines burst nearly killing him. He persisted and finally created an engine in 1893. The high compression engine, which ignites its fuel by the heat of compression is now called the Diesel engine whether a four-stroke or two-stroke design.

The four-stroke diesel engine has been used in the majority of heavy duty applications for many decades. It uses a heavy fuel containing more energy and requiring less refinement to produce. The most efficient Otto Cycle engines run near 30% efficiency.

The thermodynamic analysis of the actual four-stroke or two-stroke cycles is not a simple task. However, the analysis can be simplified significantly if air standard assumptions are utilized. The resulting cycle, which closely resembles the actual operating conditions, is the Otto cycle.

During the normal operation of the engine as the fuel mixture is being compressed an electric arc is created to ignite the fuel. At low rpm this occurs close to TDC (Top Dead Centre). As engine rpm rises the spark point is moved earlier in the cycle so that the fuel charge can be ignited while it is still being compressed. We can see this advantage reflected in the various Otto engines designs. The atmospheric (non-compression) engine operated at 12% efficiency. The compressed charge engine had an operating efficiency of 30%.

The problem with compressed charge engines is that the temperature rise of the compressed charge can cause pre-ignition. If this occurs at the wrong time and is too energetic, it can damage the engine. Different fractions of petroleum have widely varying flash points (the temperatures at which the fuel may self-ignite). This must be taken into account in engine and fuel design.

The tendency for the compressed fuel mixture to ignite early is limited by the chemical composition of the fuel. There are several grades of fuel to accommodate differing performance levels of engines. The fuel is altered to change its self ignition temperature. There are several ways to do this. As engines are designed with higher compression ratios the result is that pre-ignition is much more likely to occur since the fuel mixture is compressed to a higher temperature prior to deliberate ignition. The higher temperature more effectively evaporates fuels such as gasoline, which increases the efficiency of the compression engine. Higher Compression ratios also mean that the distance that the piston can push to produce power is greater (which is called the Expansion ratio).

The octane rating of a given fuel is a measure of the fuel's resistance to self-ignition. A fuel with a higher numerical octane rating allows for a higher compression ratio, which extracts more energy from the fuel and more effectively converts that energy into useful work while at the same time preventing engine damage from pre-ignition. High Octane fuel is also more expensive.

Diesel engines by their nature do not have concerns with pre-ignition. They have a concern with whether or not combustion can be started. The description of how likely Diesel fuel is to ignite is called the Cetane rating. Because Diesel fuels are of low volatility, they can be very hard to start when cold. Various techniques are used to start a cold Diesel engine, the most common being the use of a glow plug.

The maximum amount of power generated by an engine is determined by the maximum amount of air ingested. The amount of power generated by a piston engine is related to its size (cylinder volume), whether it is a two-stroke or four-stroke design, volumetric efficiency, losses, air-to-fuel ratio, the calorific value of the fuel, oxygen content of the air and speed (RPM). The speed is ultimately limited by material strength and lubrication. Valves, pistons and connecting rods suffer severe acceleration forces. At high engine speed, physical breakage and piston ring flutter can occur, resulting in power loss or even engine destruction. Piston ring flutter occurs when the rings oscillate vertically within the piston grooves they reside in. Ring flutter compromises the seal between the ring and the cylinder wall, which causes a loss of cylinder pressure and power. If an engine spins too quickly, valve springs cannot act quickly enough to close the valves. This is commonly referred to as 'valve float', and it can result in piston to valve contact, severely damaging the engine. At high speeds the lubrication of piston cylinder wall interface tends to break down. This limits the piston speed for industrial engines to about 10 m/s.

The output power of an engine is dependent on the ability of intake (air–fuel mixture) and exhaust matter to move quickly through valve ports, typically located in the cylinder head. To increase an engine's output power, irregularities in the intake and exhaust paths, such as casting flaws, can be removed, and, with the aid of an air flow bench, the radii of valve port turns and valve seat configuration can be modified to reduce resistance. This process is called porting, and it can be done by hand or with a CNC machine

One way to increase engine power is to force more air into the cylinder so that more power can be produced from each power stroke. This can be done using some type of air compression device known as a supercharger, which can be powered by the engine crankshaft.

Supercharging increases the power output limits of an internal combustion engine relative to its displacement. Most commonly, the supercharger is always running, but there have been designs that allow it to be cut out or run at varying speeds (relative to engine speed). Mechanically driven supercharging has the disadvantage that some of the output power is used to drive the supercharger, while power is wasted in the high pressure exhaust, as the air has been compressed twice and then gains more potential volume in the combustion but it is only expanded in one stage.

A turbocharger is a supercharger that is driven by the engine's exhaust gases, by means of a turbine. It consists of a two piece, high-speed turbine assembly with one side that compresses the intake air, and the other side that is powered by the exhaust gas outflow.

When idling, and at low-to-moderate speeds, the turbine produces little power from the small exhaust volume, the turbocharger has little effect and the engine operates nearly in a naturally aspirated manner. When much more power output is required, the engine speed and throttle opening are increased until the exhaust gases are sufficient to 'spin up' the turbocharger's turbine to start compressing much more air than normal into the intake manifold.

Turbocharging allows for more efficient engine operation because it is driven by exhaust pressure that would otherwise be (mostly) wasted, but there is a design limitation known as turbo lag. The increased engine power is not immediately available due to the need to sharply increase engine RPM, to build up pressure and to spin up the turbo, before the turbo starts to do any useful air compression. The increased intake volume causes increased exhaust and spins the turbo faster, and so forth until steady high power operation is reached. Another difficulty is that the higher exhaust pressure causes the exhaust gas to transfer more of its heat to the mechanical parts of the engine.

The rod-to-stroke ratio is the ratio of the length of the connecting rod to the length of the piston stroke. A longer rod reduces sidewise pressure of the piston on the cylinder wall and the stress forces, increasing engine life. It also increases the cost and engine height and weight.

A "square engine" is an engine with a bore diameter equal to its stroke length. An engine where the bore diameter is larger than its stroke length is an oversquare engine, conversely, an engine with a bore diameter that is smaller than its stroke length is an undersquare engine.

The valves are typically operated by a camshaft rotating at half the speed of the crankshaft. It has a series of cams along its length, each designed to open a valve during the appropriate part of an intake or exhaust stroke. A tappet between valve and cam is a contact surface on which the cam slides to open the valve. Many engines use one or more camshafts “above” a row (or each row) of cylinders, as in the illustration, in which each cam directly actuates a valve through a flat tappet. In other engine designs the camshaft is in the crankcase, in which case each cam contacts a push rod, which contacts a rocker arm that opens a valve. The overhead cam design typically allows higher engine speeds because it provides the most direct path between cam and valve.

Valve clearance refers to the small gap between a valve lifter and a valve stem that ensures that the valve completely closes. On engines with mechanical valve adjustment, excessive clearance causes noise from the valve train. A too small valve clearance can result in the valves not closing properly, this results in a loss of performance and possibly overheating of exhaust valves. Typically, the clearance must be readjusted each 20,000 miles (32,000 km) with a feeler gauge.

Most modern production engines use hydraulic lifters to automatically compensate for valve train component wear. Dirty engine oil may cause lifter failure.

Otto engines are about 30% efficient; in other words, 30% of the energy generated by combustion is converted into useful rotational energy at the output shaft of the engine, while the remainder being losses due to waste heat, friction and engine accessories. There are a number of ways to recover some of the energy lost to waste heat. The use of a Turbocharger in Diesel engines is very effective by boosting incoming air pressure and in effect provides the same increase in performance as having more displacement. The Mack Truck company, decades ago, developed a turbine system that converted waste heat into kinetic energy that it fed back into the engine's transmission. In 2005, BMW announced the development of the turbosteamer, a two-stage heat-recovery system similar to the Mack system that recovers 80% of the energy in the exhaust gas and raises the efficiency of an Otto engine by 15%. By contrast, a six-stroke engine may reduce fuel consumption by as much as 40%.

Modern engines are often intentionally built to be slightly less efficient than they could otherwise be. This is necessary for emission controls such as exhaust gas recirculation andcatalytic converters that reduce smog and other atmospheric pollutants. Reductions in efficiency may be counteracted with an engine control unit using lean burn techniques.

In the United States, the Corporate Average Fuel Economy mandates that vehicles must achieve an average of 34.9 miles per gallon (mpg) compared to the current standard of 25 mpg. As automakers look to meet these standards by 2016, new ways of engineering the traditional internal combustion engine (ICE) could have to be considered. Some potential solutions to increase fuel efficiency to meet new mandates include firing after the piston is farthest from the crankshaft, known as top dead centre, and applying theMiller cycle. Together, this redesign could significantly reduce fuel consumption and NOx emissions.

Starting

position, intake stroke, and compression stroke.

Ignition of fuel, power

stroke, and exhaust stroke.

Gasoline or petrol engines are also known as spark-ignition (S.I.) engines. Petrol engines take in a flammable mixture of air and petrol which is ignited by a timed spark when the charge is compressed. The first four stroke spark-ignition (S.I.) engine was built in 1876 by Nicolaus August Otto, a self-taught German engineer at the Gas-motoreufabrik Deutz factory near Cologne, for many years the largest manufacturer of internal-combustion engines in the world. It was one of Otto's associates - Gottlieb Daimler - who later developed an engine to run on petrol which was described in patent number 4315 of 1885. He also pioneered its application to the motor vehicle (Fig. 1.1-3).

Four stroke Spark-ignition (S.I) engines require four piston strokes to complete one cycle: an air-and-fuel intake stroke moving outward from the cylinder head, an inward movement towards the cylinder head compressing the charge, an outward power stroke, and an inward exhaust stroke.

Induction stroke (Fig. 1.1-3(a)) The inlet valve is opened and the exhaust valve is closed. The piston descends, moving away from the cylinder head (Fig. 1.1-3(a)). The speed of the piston moving along the cylinder creates a pressure reduction or depression which reaches a maximum of about 0.3 bar below atmospheric pressure at one-third from the beginning of the stroke. The depression actually generated will depend on the speed and load experienced by the engine, but a typical average value might be 0.12 bar below atmospheric pressure. This depression induces (sucks in) a fresh charge of air and atomized petrol in proportions ranging from 10 to 17 parts of air to one part of petrol by weight.

An engine which induces fresh charge by means of a depression in the cylinder is said to be 'normally aspirated' or 'naturally aspirated'.

Compression stroke (Fig. 1.1-3(b)) Both the inlet and the exhaust valves are closed. The piston begins to ascend towards the cylinder head (Fig. 1.1-3(b)). The induced air-and-petrol charge is progressively compressed to something of the order of one-eighth to one-tenth of the cylinder's original volume at the piston's innermost position. This compression squeezes the air and atomized-petrol molecules closer together and not only increases the charge pressure in the cylinder but also raises the temperature. Typical maximum cylinder compression pressures will range between 8 and 14 bar with the throttle open and the engine running under load.

Power stroke (Fig. 1.1-3(c)) Both the inlet and the exhaust valves are closed and, just before the piston approaches the top of its stroke during compression, a spark-plug ignites the dense combustible charge (Fig. 1.1-3(c)). By the time the piston reaches the innermost point of its stroke, the charge mixture begins to burn, generates heat, and rapidly raises the pressure in the cylinder until the gas forces exceed the resisting load. The burning gases then expand and so change the piston's direction of motion and push it to its outermost position. The cylinder pressure then drops from a peak value of about 60 bar under full load down to maybe 4 bar near the outermost movement of the piston.

Exhaust stroke (Fig. 1.1-3(d)) At the end of the power stroke the inlet valve remains closed but the exhaust valve is opened. The piston changes its direction of motion and now moves from the outermost to the innermost position (Fig. 1.1-3(d)). Most of the burnt gases will be expelled by the existing pressure energy of the gas, but the returning piston will push the last of the spent gases out of the cylinder through the exhaust-valve port and to the atmosphere. During the exhaust stroke, the gas pressure in the cylinder will fall from the exhaust-valve opening pressure (which may vary from 2 to 5 bar, depending on the engine speed and the throttle-opening position) to atmospheric pressure or even less as the piston nears the innermost position towards the cylinder head.

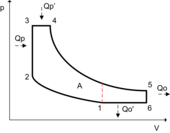

Cycle of events in a four-cylinder engine (Figs. 1.1-3(e)-(g)) Fig. 1.1-3(e) illustrates how the cycle of events - induction, compression, power, and exhaust - is phased in a four-cylinder engine. The relationship between cylinder pressure and piston stroke position over the four strokes is clearly shown in Figs. 1.1-3(f) and (g) and, by following the arrows, it can be seen that a figures of eight is repeatedly being traced.

The differences between two- and four-stroke-cycle petrol engines regarding the effectiveness of both engine cycles are given below:

a) The two-stroke engine completes one cycle of events for every revolution of the crankshaft, compared with the two revolutions required for the four-stroke engine cycle.

b) Theoretically, the two-stroke engine should develop twice the power compared to a four-stroke engine of the same cylinder capacity.

c) In practice, the two-stroke engine's expelling of the exhaust gases and filling of the cylinder with fresh mixture brought in through the crankcase is far less effective than having separate exhaust and induction strokes. Thus the mean effective cylinder pressures in two-stroke units are far lower than in equivalent four-stroke engines.

d) With a power stroke every revolution instead of every second revolution, the two-stroke engine will run smoother than the four-stroke power unit for the same size of flywheel.

e) Unlike the four-stroke engine, the two-stroke engine does not have the luxury of separate exhaust and induction strokes to cool both the cylinder and the piston between power strokes. There is therefore a tendency for the piston and small-end to overheat under heavy driving conditions.

f) Due to its inferior scavenging process, the two-stroke engine can suffer from the following:

i) inadequate transfer of fresh mixture into the cylinder,

ii) excessively large amounts of residual exhaust gas remaining in the cylinder,

iii) direct expulsion of fresh charge through the exhaust port. These undesirable conditions may occur under different speed and load situations, which greatly influences both power and fuel consumption.

g) Far less maintenance is expected with the two-stroke engine compared with the four-stroke engine, but there can be a problem with the products of combustion carburizing at the inlet, transfer, and exhaust ports.

h) Lubrication of the two-stroke engine is achieved by mixing small quantities of oil with petrol in proportions anywhere between 1:16 and 1:24 so that, when crankcase induction takes place, the various rotating and reciprocating components will be lubricated by a petrol-mixture mist. Clearly a continuous proportion of oil will be burnt in the cylinder and expelled into the atmosphere to add to unwanted exhaust emission.

i) There are fewer working parts in a two-stroke engine than in a four-stroke engine, so two-stroke engines are generally cheaper to manufacture.

A brief but critical comparison of two and four stroke diesel engine is made below:

a) Theoretically, almost twice the power can be developed with a two-stroke engine compared with a four-stroke engine.

b) A comparison between a typical 12 liter four-stroke engine and a 7 liter two-stroke engine having the same speed range would show that they would develop similar torque and power ratings. The ratio of engine capacities for equivalent performance for these four-stroke and two-stroke engines would be 1.7:1.

c) In a four-stroke engine, the same parts generate power and empty and fill the cylinders. With the two-stroke engine, the emptying and filling can be carried out by light rotary components.

d) With a two-stroke engine, 40–50% more air consumption is necessary for the same power output; therefore the air-pumping work done will be proportionally greater.

e) About 10–20% of the upward stroke of a two-stroke engine must be sacrificed to emptying and filling the cylinder.

f) The time available for emptying and filling a cylinder is considerably less in a two-stroke-cycle engine – something like 33% of the completed cycle as compared to 50% in a four-stroke engine. Therefore more power will be needed to force a greater mass of air into the cylinder in a shorter time.

g) Compared with a two-stroke engine, more power is needed by the piston for emptying and filling the cylinder in a four-stroke engine, due to pumping and friction losses at low speeds. At higher engine speeds the situation is reversed, and the two-stroke’s Rootes blower will consume proportionally more engine power – this could be up to 15% of the developed power at maximum speed.

h) With reduced engine load for a given speed, a two-stroke engine blower will consume proportionally more of the power developed by the engine.

i) A two-stroke engine runs smoother and relatively quietly, due to the absence of reversals of loading on bearings as compared with a four-stroke engine.

Compression-ignition (C.I) engines burn fuel oil which is injected into the combustion chamber when the air charge is fully compressed. Burning occurs when the compression temperature of the air is high enough to spontaneously ignite the finely atomized liquid fuel. In other words, burning is initiated by the self-generated heat of compression (Fig. 1.1-8). Compression-ignition (C.I) engines are also referred to as 'oil engines', due to the class of fuel burnt, or as 'diesel engines' after Rudolf Diesel, one of the many inventors and pioneers of the early C.I. engine. Note: in the United Kingdom fuel oil is known as 'DERV', which is the abbreviation of 'diesel-engine road vehicle'.

Just like the four-stroke-cycle petrol engine, the Compression-ignition (C.I.) engine completes one cycle of events in two crankshaft revolutions or four piston strokes. The four phases of these strokes are (i) induction of fresh air, (ii) compression and heating of this air, (iii) injection of fuel and its burning and expansion, and (iv) expulsion of the products of combustion.

Induction stroke (Fig. 1.1-8(a)) With the inlet valve open and the exhaust valve closed, the piston moves away from the cylinder head (Fig. 1.1-8(a)).

The outward movement of the piston will establish a depression in the cylinder, its magnitude depending on the ratio of the cross-sectional areas of the cylinder and the inlet port and on the speed at which the piston is moving. The pressure difference established between the inside and outside of the cylinder will induce air at atmospheric pressure to enter and fill up the cylinder. Unlike the petrol engine, which requires a charge of air-and-petrol mixture to be drawn past a throttle valve, in the diesel-engine inlet system no restriction is necessary and only pure air is induced into the cylinder. A maximum depression of maybe 0.15 bar below atmospheric pressure will occur at about one-third of the distance along the piston's outward stroke, while the overall average pressure in the cylinder might be 0.1 bar or even less.

Compression stroke (Fig. 1.1-8(b)) With both the inlet and the exhaust valves closed, the piston moves towards the cylinder head (Fig. 1.1-8(b)).

The air enclosed in the cylinder will be compressed into a much smaller space of anything from 1/12 to 1/24 of its original volume. A typical ratio of maximum to minimum air-charge volume in the cylinder would be 16:1, but this largely depends on engine size and designed speed range.

During the compression stroke, the air charge initially at atmospheric pressure and temperature is reduced in volume until the cylinder pressure is raised to between 30 and 50 bar. This compression of the air generates heat which will increase the charge temperature to at least 600 °C under normal running conditions.

Power stroke (Fig. 1.1-8(c)) With both the inlet and the exhaust valves closed and the piston almost at the end of the compression stroke (Fig. 1.1 -8(c)), diesel fuel oil is injected into the dense and heated air as a high-pressure spray of fine particles. Provided that they are properly atomized and distributed throughout the air charge, the heat of compression will then quickly vaporize and ignite the tiny droplets of liquid fuel. Within a very short time, the piston will have reached its innermost position and extensive burning then releases heat energy which is rapidly converted into pressure energy. Expansion then follows, pushing the piston away from the cylinder head, and the linear thrust acting on the piston end of the connecting-rod will then be changed to rotary movement of the crankshaft.

Exhaust stroke When the burning of the charge is near completion and the piston has reached the outermost position, the exhaust valve is opened. The piston then reverses its direction of motion and moves towards the cylinder head (Fig. 1.1-8(d)).

The sudden opening of the exhaust valve towards the end of the power stroke will release the still burning products of combustion to the atmosphere. The pressure energy of the gases at this point will accelerate their expulsion from the cylinder, and only towards the end of the piston's return stroke will the piston actually catch up with the tail-end of the outgoing gases.

Fig. 1.1-8(e) illustrates the sequence of the four operating strokes as applied to a four-cylinder engine, and the combined operating events expressed in terms of cylinder pressure and piston displacement are shown in Figs. 1.1-8(f) and (g).

Sri neelakanteswara ITI